ABOUT US

Power-efficient electrical connectors.

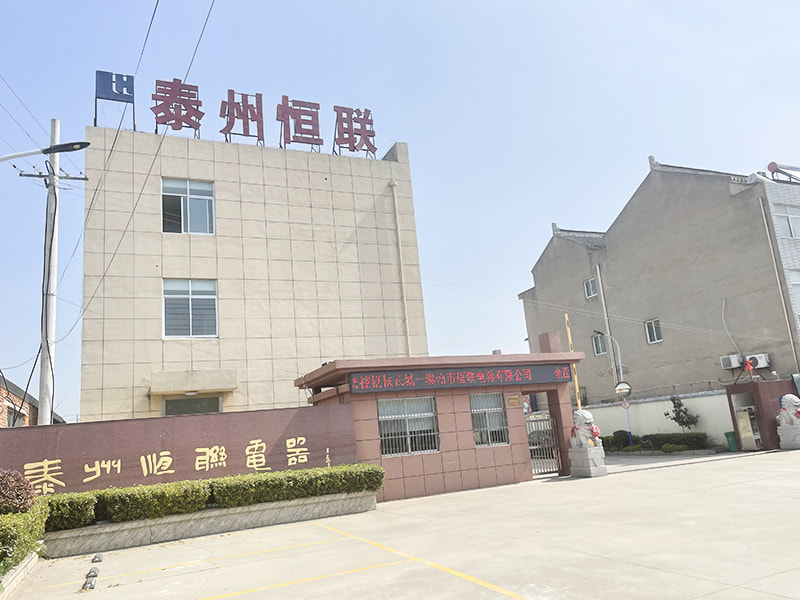

Taizhou Henglian Electric Co., Ltd. was founded in April 2011, is located in the "Ginkgo town" reputation of the riverside city - Taixing City, is specialized in electrical connector development, production, sales of high-tech enterprises.

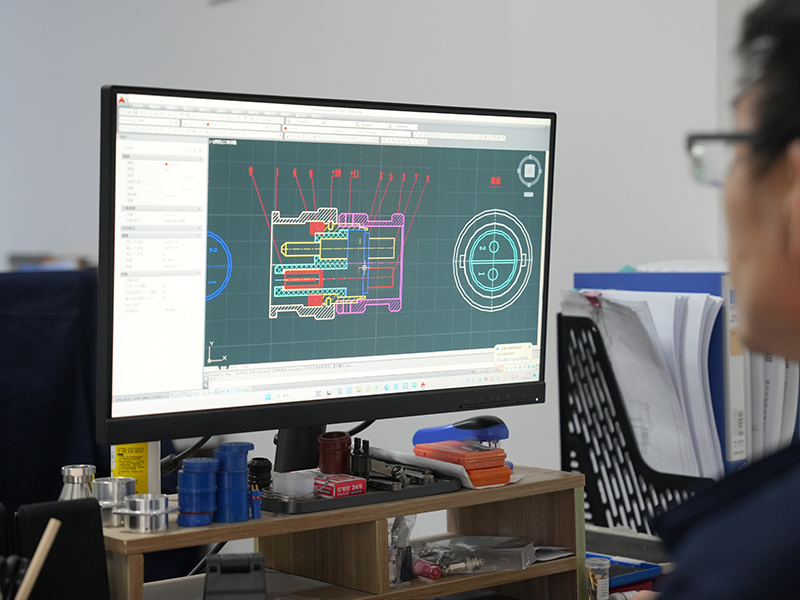

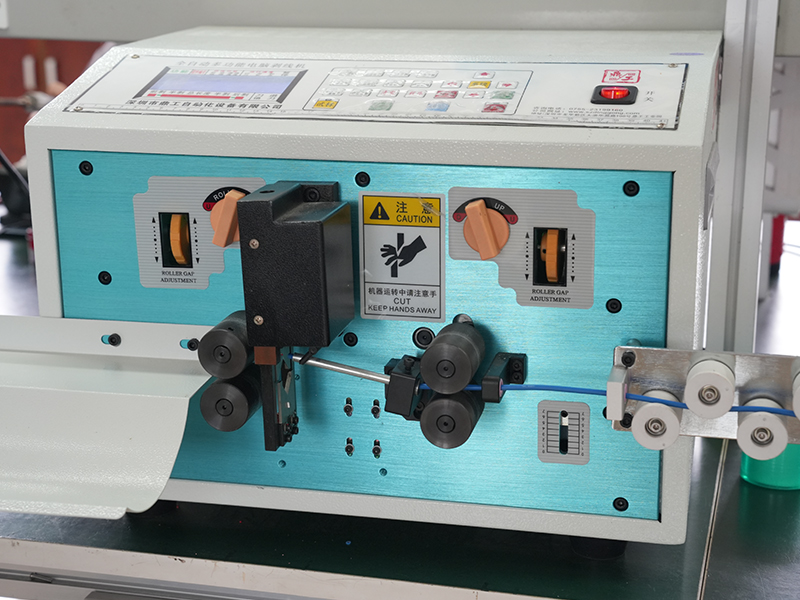

We are China Custom D38999 Series III Military Bayonet Electrical Connectors Manufacturers and OEM/ODM D38999 Series III Military Bayonet Electrical Connectors Suppliers.There are more than 150 employees, including more than 30 people with various professional and technical titles, fixed assets of 30 million yuan, with a variety of mechanical processing equipment and testing equipment.

In recent years, the company has been rated as "Top Ten enterprises in Zhangqiao Town", "Top Ten enterprises in Zhangqiao Town", and won the "Taixing Outstanding Contribution Award" and other titles.

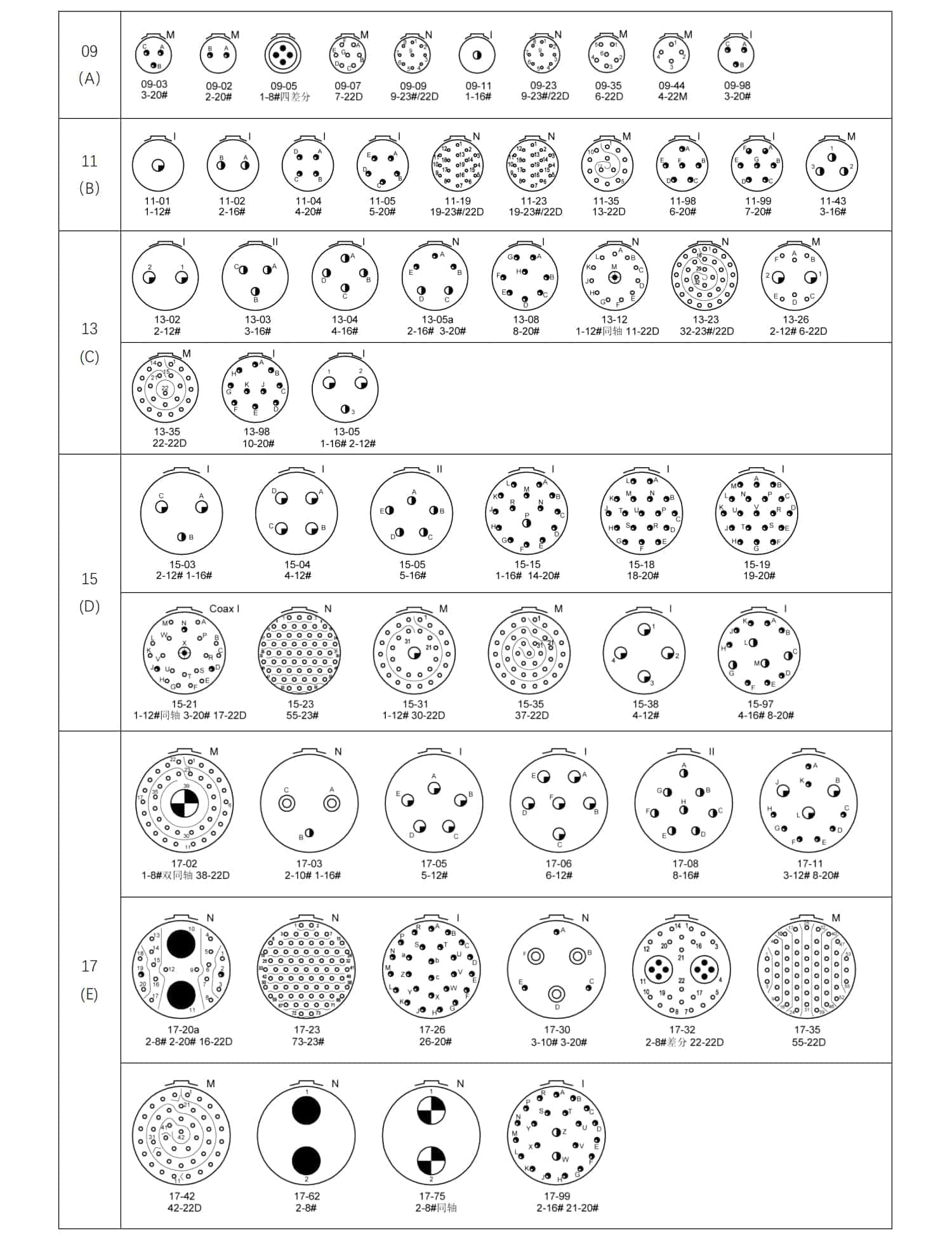

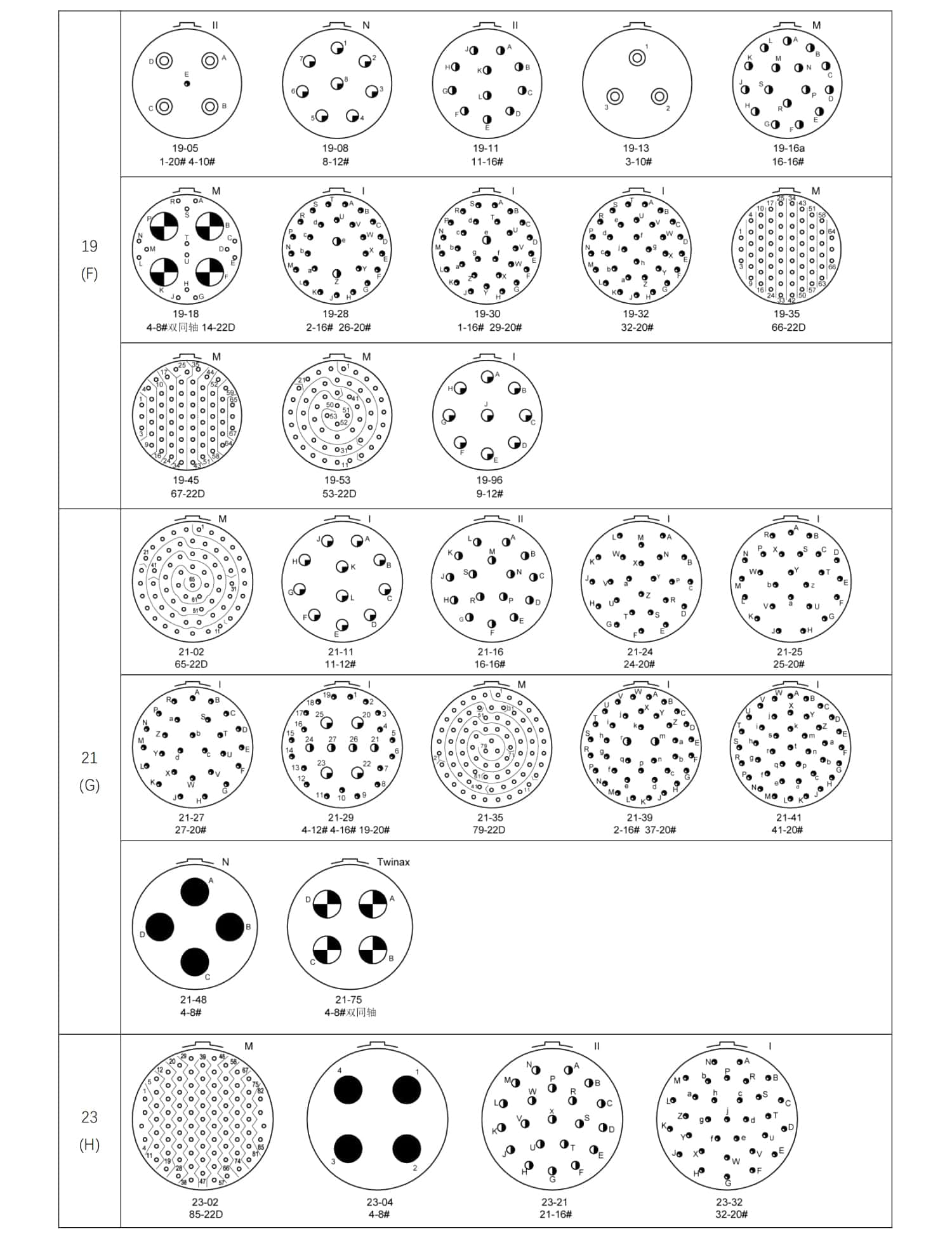

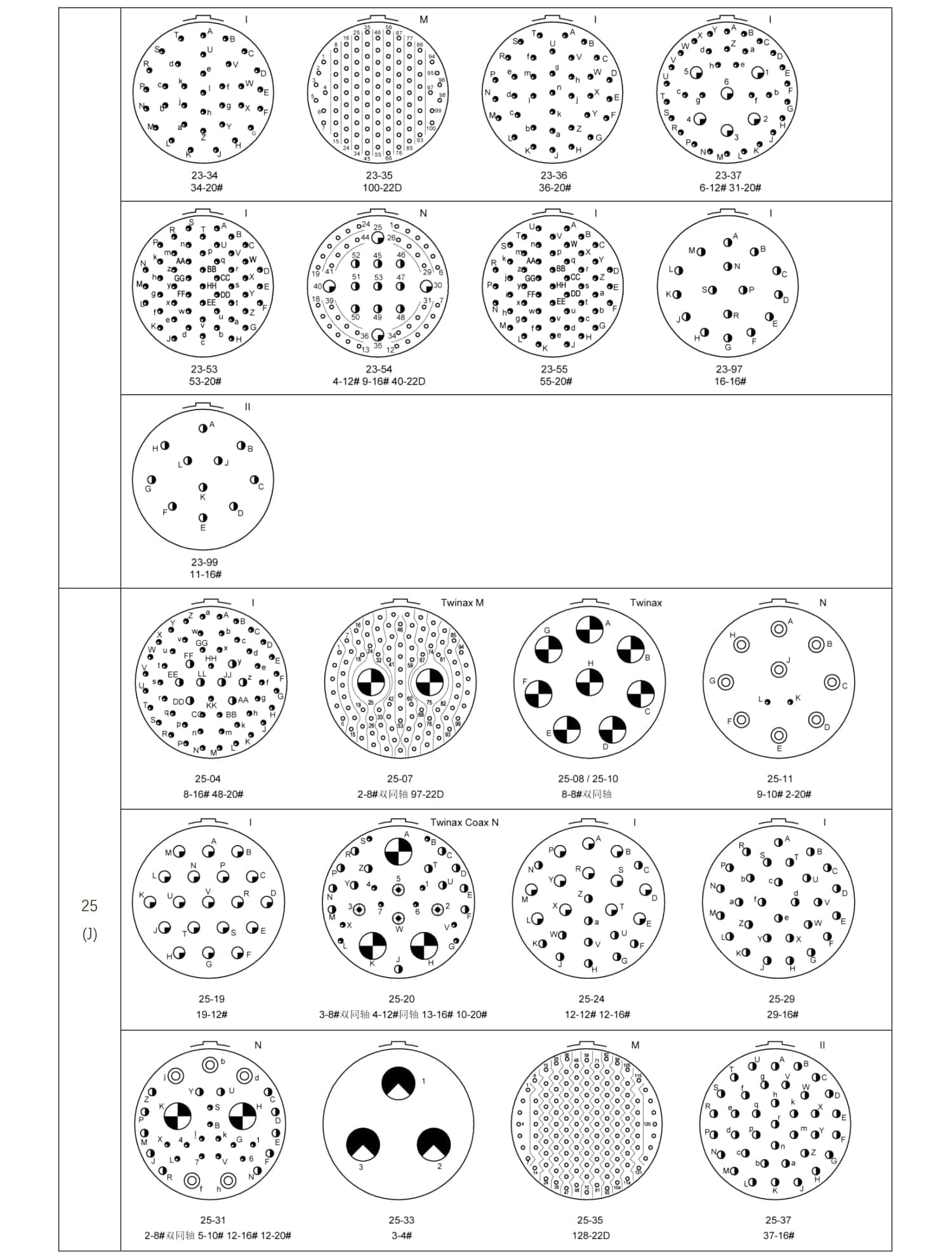

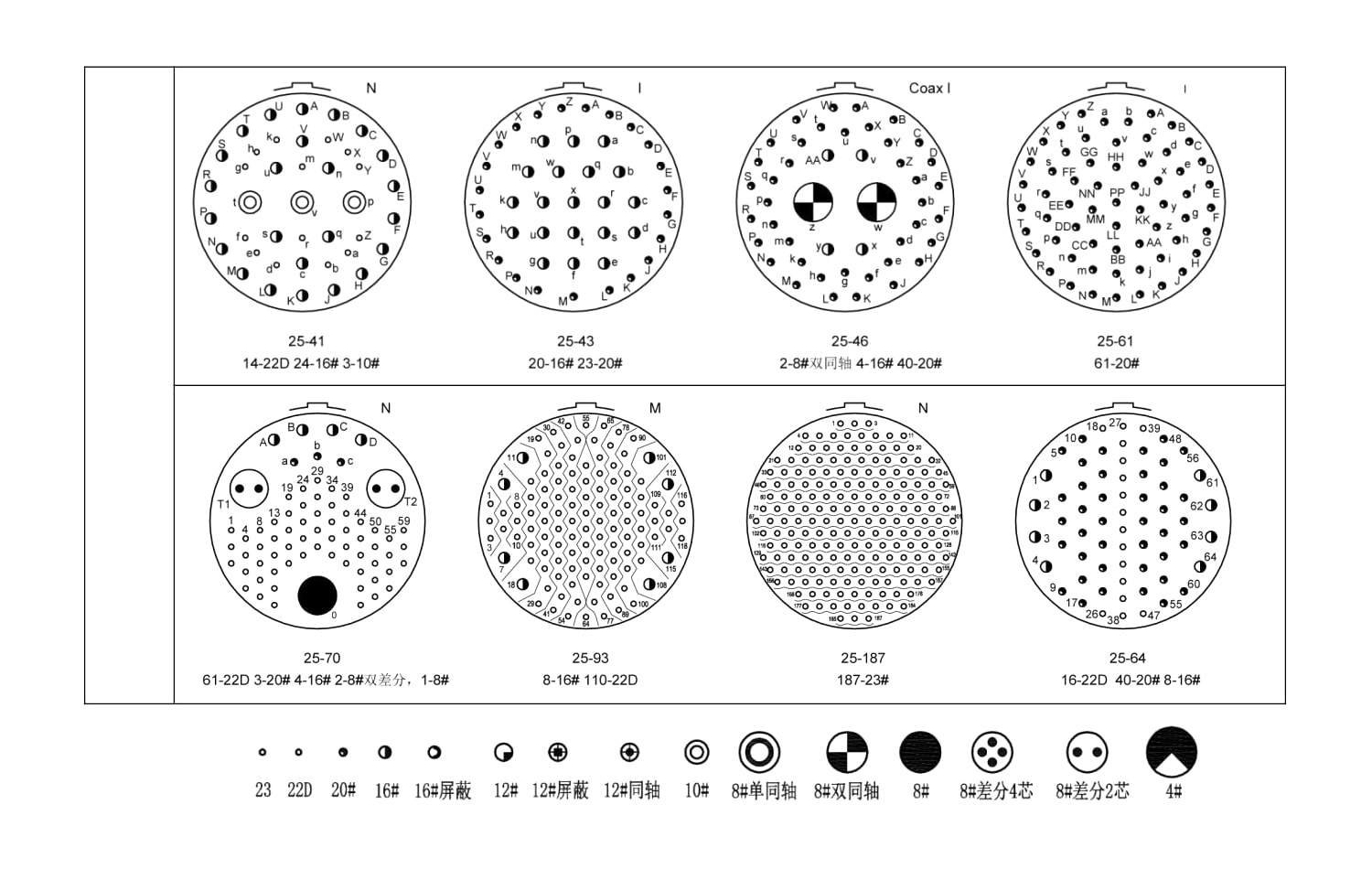

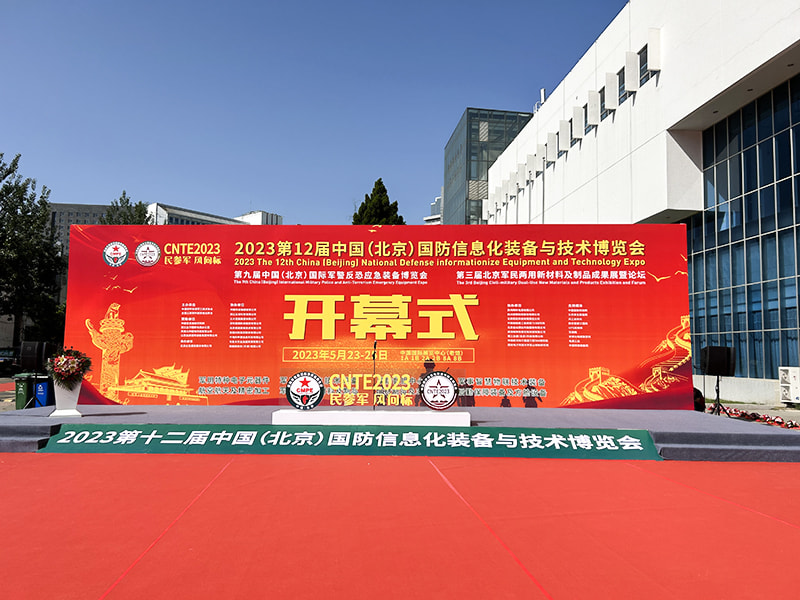

At present, the company's leading products are conforming to the military standard Y11, Y17, Y27, Y50, YGD, YLH, YM, YW, J599I, J599II, J599III, XC series circular electrical connectors, and J7, J14, J20J, J29A, J30J, J63A series rectangular electrical connectors. It is in line with the national standard Y2, Y4, YP, LYP, YD, and other series of circular electric connectors. The products cover the general staff, final assembly, sea installation, Second Artillery, weapons, aerospace and other military varieties nuclear energy, railway, national power grid, oil earth geophysical exploration, and other fields. The company has a technical center, and quality inspection center, with sophisticated production equipment, modern inspection facilities, and inspection and testing means. The products have the characteristics of three-defense function, high density, high reliability, electronic compatibility, etc., and can develop and produce various kinds of special electrical connectors for various users to meet customer needs.

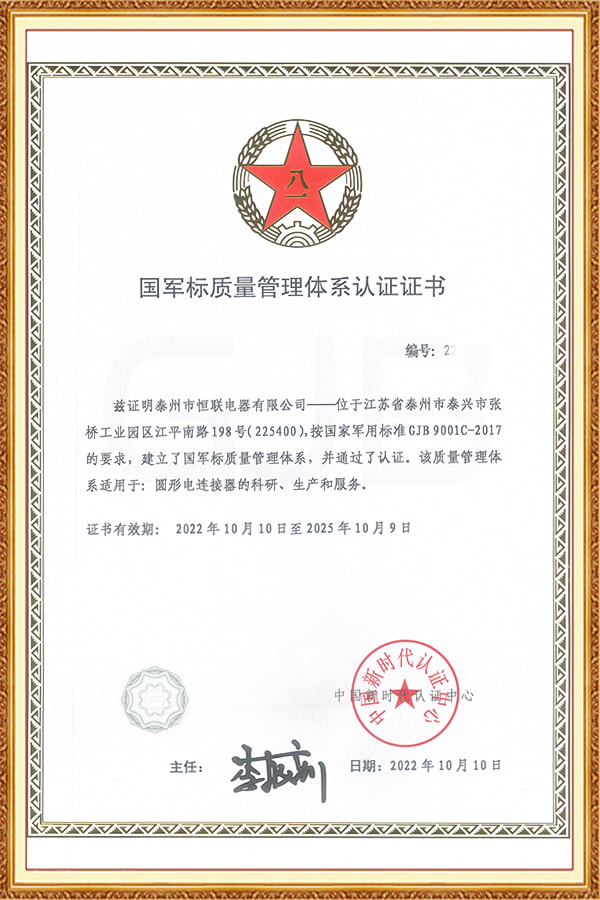

The company is a qualified supplier of military electronic components, Marine equipment and aerospace of the Communications Department of the General Staff and the Ministry of Information Industry, and has passed the GJB9001C-2017 weapons and equipment quality management system certification and the second-level secret certification of weapons and equipment production and research units.

The company always adhere to the "integrity-based, unity and hard work, realistic innovation, the pursuit of excellence" spirit of enterprise, adhere to the concept of "brand create value", dedicated to customer service, so that Henglian quickly become the leader in the peer.

Taizhou Henglian Electric Co., Ltd. sincerely welcome domestic and foreign customers to visit and negotiate business!

-

In the high-stakes environment of industrial automation and robotics, the failure of a single connection can lead to cat...

READ MORE -

In the high-stakes world of aerospace, defense, and industrial automation, the complexity of cable management often beco...

READ MORE -

In the world of high-performance electronics, the integrity of a connection is defined not just by its electrical conduc...

READ MORE -

In the high-stakes domain of aerospace engineering, the integrity of an electrical interconnect system can be the differ...

READ MORE -

In the realm of advanced electronic packaging, the geometry of a component often dictates the overall limits of system m...

READ MORE

How to Choose the Right D38999 Series III Military Bayonet Electrical Connector: Electrical and Mechanical Parameter Guide

1. Electrical Parameter Selection Guide

When selecting a D38999 Series III connector, it is crucial to consider electrical performance due to its widespread use in military, aerospace, nuclear energy, power, and geophysical exploration. Key electrical parameters include:

| Parameter | Typical Value/Range | Description |

|---|---|---|

| Voltage Rating | 500V – 1500V RMS | Choose insulation level based on equipment requirements |

| Current Rating | 3A – 50A/contact | Related to wire diameter and contact type |

| Contact Resistance | ≤5 mΩ | Ensures low loss and high reliability |

| Insulation Resistance | ≥5000 MΩ | Enhances leakage resistance and environmental tolerance |

| Contact Type | Pin-Socket, Coaxial, etc. | Select according to signal type or power requirement |

| EMI/RFI Shielding | Yes/No | Designed for sensitive signals or high-frequency environments |

Tip: Connectors from Taizhou Henglian Electric Co., Ltd. feature high reliability, strong electronic compatibility, and three-defense functions (waterproof, dustproof, corrosion-resistant) suitable for extreme environments.

2. Mechanical Parameter Selection Guide

D38999 Series III connectors are known for mechanical strength and ease of installation. Key mechanical parameters include:

| Parameter | Typical Value/Range | Description |

|---|---|---|

| Connector Type | Bayonet | Quick connect/disconnect, suitable for military and aerospace applications |

| Shell Material | Aluminum Alloy, Steel, Stainless Steel | Choose based on strength and corrosion resistance requirements |

| Protection Level | IP67 – IP68 | Suitable for underwater or high-humidity environments |

| Temperature Range | -65°C to +200°C | Meets extreme high and low temperature requirements |

| Vibration Resistance | 10-2000Hz, 20g | Ensures no detachment during transportation or operation |

| Durability | ≥500 mating cycles | High-strength repeated use suitability |

Tip: Taizhou Henglian Electric Co., Ltd. has advanced machining and testing equipment to ensure each batch meets strict military and aerospace mechanical standards.

3. Application and Standard Matching

When choosing a connector, consider the application scenario:

- Military Equipment: Certified with GJB9001C-2017 and Level 2 security clearance, supporting Second Artillery, Navy equipment, etc.

- Aerospace: High density, high reliability, and strong electronic compatibility.

- Energy and Railways: Corrosion-resistant, waterproof, and dustproof for extreme outdoor environments.

Taizhou Henglian Electric Co., Ltd. offers Y11, Y17, Y27, Y50, YGD, YLH, YM, YW, J599I/II/III, and XC series circular connectors, as well as J7, J14, J20J, J29A, J30J, J63A rectangular connectors, with customization available for special requirements.

4. Parameter Comparison Example

| Connector Model | Current Rating | Voltage Rating | Temperature Range | Protection Level | Application |

|---|---|---|---|---|---|

| D38999 Series III, 9-pin | 5A | 500V | -65°C ~ +175°C | IP67 | Aviation, Communication |

| D38999 Series III, 25-pin | 7A | 600V | -55°C ~ +200°C | IP68 | Military Vehicles, Navy Equipment |

| D38999 Series III, 37-pin | 10A | 1000V | -65°C ~ +200°C | IP68 | Aerospace, Nuclear Energy, Oil Exploration |

Recommendation: Evaluate current, voltage, pin count, and environmental conditions comprehensively to select the most suitable model.

5. Importance of Supplier Selection

Choosing the right connector also depends on the supplier’s R&D, production, and quality control capabilities. Taizhou Henglian Electric Co., Ltd. features:

- Technical and quality inspection centers to ensure military-grade design and production.

- High-precision machining and testing equipment to guarantee product reliability.

- Customization capability to meet special environmental and application needs.

By combining electrical and mechanical parameters with supplier capability, users can efficiently select D38999 Series III connectors to ensure stable performance in high-risk environments.

English

English русский

русский Español

Español 简体中文

简体中文